DOOR HANDEL?

The first records of the term door handle come from around 1830. The word doorknob is first recorded soon after, around the 1840s.

A door handle is an attached mechanism used to open or close a door. In the United States, door handle generally can refer to any fixed or lever-operated door latch device, including on car doors. The term door knob tends to refer to round operating mechanisms.

Door handles on the doors inside a home, like on a bathroom or a closet, often jut out from the door to allow for easy grabbing and turning. They’re such a common part of daily life that we often don’t notice them or think about them—unless they break.

ZINC METAL

ZINC CASTING METALS

We have produced Thousands of zincs die cast components—from one hundredth of a gram to one kilogram in size.

Zinc alloy characteristics:

- ⦁ High strength and hardness

- ⦁ Excellent electrical conductivity

- ⦁ High thermal conductivity

- ⦁ Low-cost raw material

- ⦁ High dimensional accuracy and stability

- ⦁ Excellent thin wall capability

- ⦁ High quality finishing characteristics

- ⦁ Full recyclability

Zinc’s high strength and hardness lends itself to many solutions and it’s the ideal alternative to machined, pressed, stamped, and fabricated components.

Applications for Zinc:

- ⦁ Complex net-shaped zinc housings, with precise thin walls offer excellent electrical performance and shielding properties

- ⦁ Our proprietary multi-slide die casting process and superior thin-wall capabilities make us the foremost supplier of zinc components for broad range of consumer electronic devices

ZAMAK 3

Zamak 3 (ASTM AG40A), or Zinc Alloy 3, is the most widely used zinc alloy in North America And India and is usually the first choice when considering zinc for die casting for a number of reasons.

- ⦁ Excellent balance of desirable physical and mechanical properties

- ⦁ Superb castability and long-term dimensional stability

- ⦁ Excellent finishing characteristics for plating, painting, and chromate treatments

- * Excellent damping capacity and vibration attenuation in comparison to aluminium die cast alloys

When it comes to die casting, Zamak 3 is the standard by which other zinc alloys are rated. We Use ZAMAK-3 For All of Our Product for Giving Good tensile Strength and Hardness of Product.

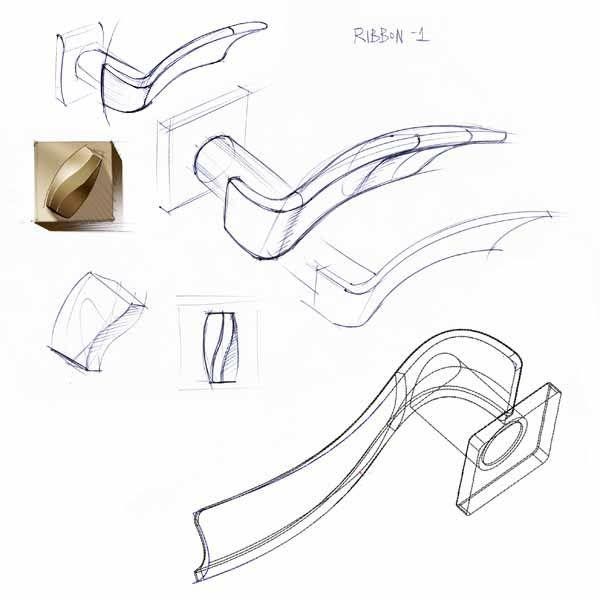

DESIGN FOR HANDEL

Our dedicated team of over one hundred highly trained and experienced engineers will work with you from early in your project to ensure your component is designed with manufacturing in mind, so you avoid expensive secondary operations like machining or extra assembly steps. Our goal is always to determine the best design, materials and methods which will deliver optimum results for your product.

R&D: Research and Development

Backed by a robust R&D team, SAGA is now a leader in designing and developing products that integrate cutting-edge technology, meet unique and specific requirements in both standard and custom products, and fast time-to-market. Even from the initial planning phase of product development, SAGA engages various departments to study and discuss all the relevant processes including logistics, design, manufacturing and quality control, to identify, meet and even exceed customer demands. In addition to meeting demands for quality, SAGA's team aims to reduce costs and shorten the development process, and attend to all matters leading to the overall satisfaction of clients.

Process

Casting Process

Although casting is one of the oldest known manufacturing techniques, modern advances in casting technology have led to a broad array of specialized casting methods. Hot forming processes, such as die-casting, investment casting, plaster casting, and sand casting, each provide their own unique manufacturing benefits. Comparing both the advantages and disadvantages of the common types of casting processes can help in selecting the method best suited for a given production run.

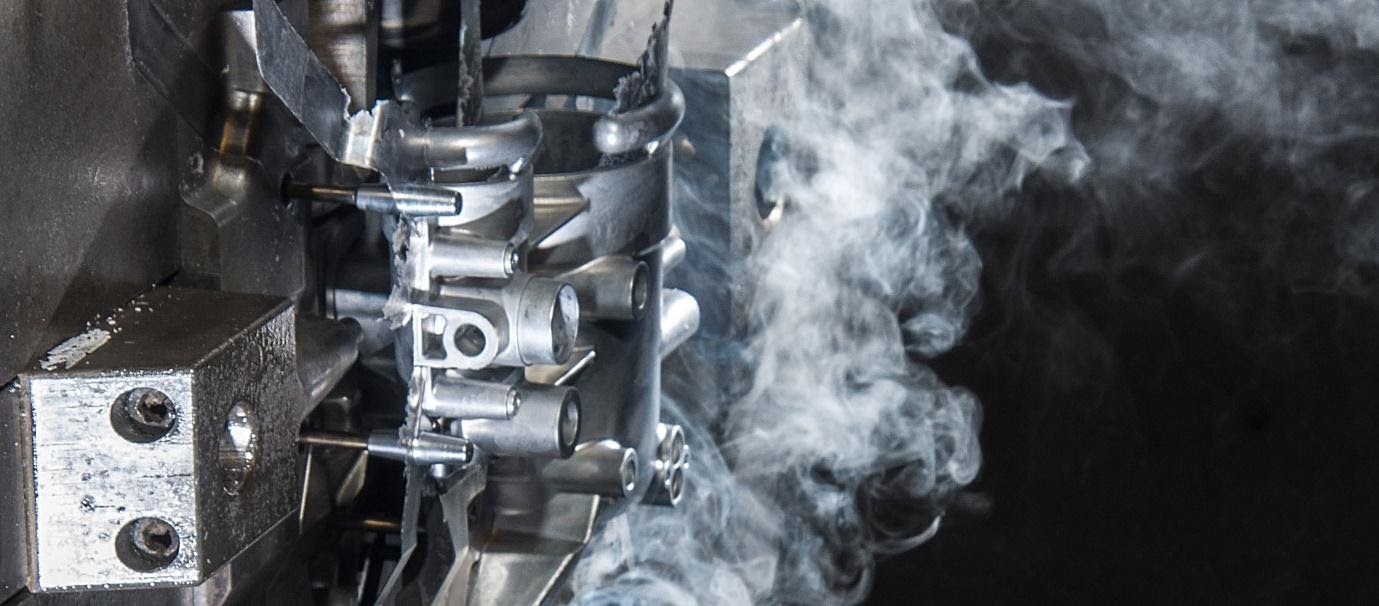

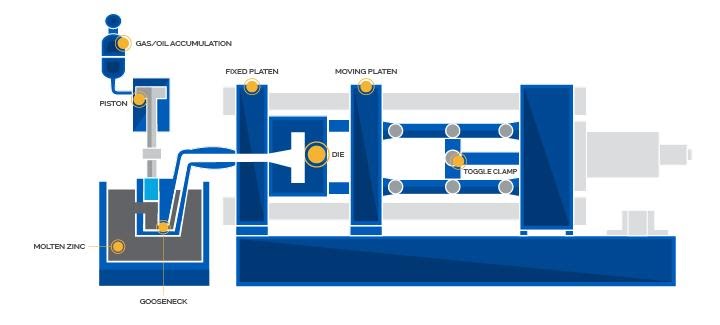

1. Die Casting (Metal Casting Process)

Die casting is a method of moulding materials under high pressure and usually involves non-ferrous metals and alloys, such as zinc, tin, copper, and aluminium. The reusable mould is coated with a lubricant to help regulate the die’s temperature and to assist with component ejection. Molten metal is then injected into the die under high pressure, which remains continuous until the workpiece solidifies. This pressurized insertion is rapid, preventing any segment of the material from hardening before being cast. After the process is completed, the component is taken out of the die and any scrap material is removed. A few of the major advantages provided by die casting include:.

- ⦁ Close size and shape tolerances.

- ⦁ High component dimensional consistency and uniform design.

- ⦁ A reduced need for post-casting machining

Despite its advantages, die casting as a metal casting process has relatively high tool costs, making it more cost-efficient in high-volume product runs. It can also be difficult to ensure the mechanical properties of a die-cast component, meaning these products usually do not function as structural parts. As the moulds are typically two-piece, die casting is limited to products that can be removed from the mould without destroying the mould, as is done in other casting processes.

For more information on Die Casting, you can review our Types of Die Casting guide, which goes into depth on the various types, alloys, and considerations for choosing a specific process/alloy combination.

2. MACHINING

There is usually very little machining required on our precision zinc die castings because of the accuracy we obtain. The machining characteristics of zinc and zinc alloys are excellent and a wide range of machining processes can generally be used.

Drilling — we can achieve better, more economical drilling under a wide range of operating conditions. To find out how, contact us directly

Tapping — zinc die casting alloys are readily tapped and form excellent thread and hole quality. Threads can be cut or formed with and without lubricants and can be easily tapped using fluteless taps to produce a rolled thread. Fluteless tapping is carried out at higher speeds than cutting taps, and lubrication is essential.

Reaming — our precision zinc die casting process is so precise that holes are cored to the required size for reaming. This means we avoid drilling operations requiring the manufacturing of expensive jigs.

3. ELECTO-PLATTING

Allows the product to be finished in an attractive manner allowing not only aesthetic use but also protection from acidic or high salt content water.

In this process, first a base coating of electroplated nickel is first applied, followed by a thin coating of electroplated chromium. The chrome layer is deposited from a plating bath containing certain additives that improve corrosion resistance. The chrome layers are impossibly thin, less than the thickness of a human hair.

4. POLISHING

"Buffing" is the process used to shine metal, wood, or composites using a cloth wheel impregnated with cutting compounds or rouges. The cloth buff "holds" or "carries" the compound, while the compound does the cutting.

The industry refers to "polishing" as the process, which uses abrasive belt finishing.

Buffing generally requires two operations, a cut buff and a finish buff. Even the cut buff, which is the coarsest buffing operation, is too fine for removal of pits, course abrasive polishing lines, or deep scratches. This is why surface preparation prior to buffing is critical to a high luster, final finish.

5. INCPECTION FOR HANDELS

Overview

In addition to our rigorous fire and security testing and certification capabilities, we offer the ability to conduct performance testing of door hardware and door sets to widely recognized European Norm (EN), Builders Hardware Manufacturers Association (BHMA) and SDI test standards. Performance testing can include various strength, physical endurance, corrosion and operational tests as prescribed in various standards for door hinges, locks, closers and panic exit hardware. These tests are intended to help ensure that the door hardware performs as intended over the lifetime of the product and the door opening. The door hardware testing service complements other testing capabilities we offer for fire, security, severe weather and for other potential harms.

Benefits

Our testing capabilities allow you to use one provider to fulfil a wide variety of door opening testing needs simultaneously. These capabilities reduce the time taken to determine product compliance, gain the regulatory approvals, and undertake the commercial testing required. It’s our goal to help ensure access to global markets faster.

In addition to the health check process, regular hardware inspection and maintenance helps to support the optimal performance. Periodically inspect the components of the Product. To give premium And Quality product we test our product in every possible situation and also Follow the Quality Testing Standards for Our Products.

6. PACKING

Parts packagers handle a variety of products from nuts and washers to gears and Mechanical components. And the packaging requirements are equally diverse, from bagging to skin and blister packaging.

Package your parts quickly, efficiently, and at the lowest possible cost.

Our packaging experts know how to assemble and pack small, difficult, even greasy parts commonly used in a variety of industrial applications. Our packaging services and equipment specialists can bag, skin package, and blister pack all of your parts so you can get to market quickly.